You have a

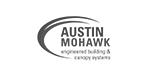

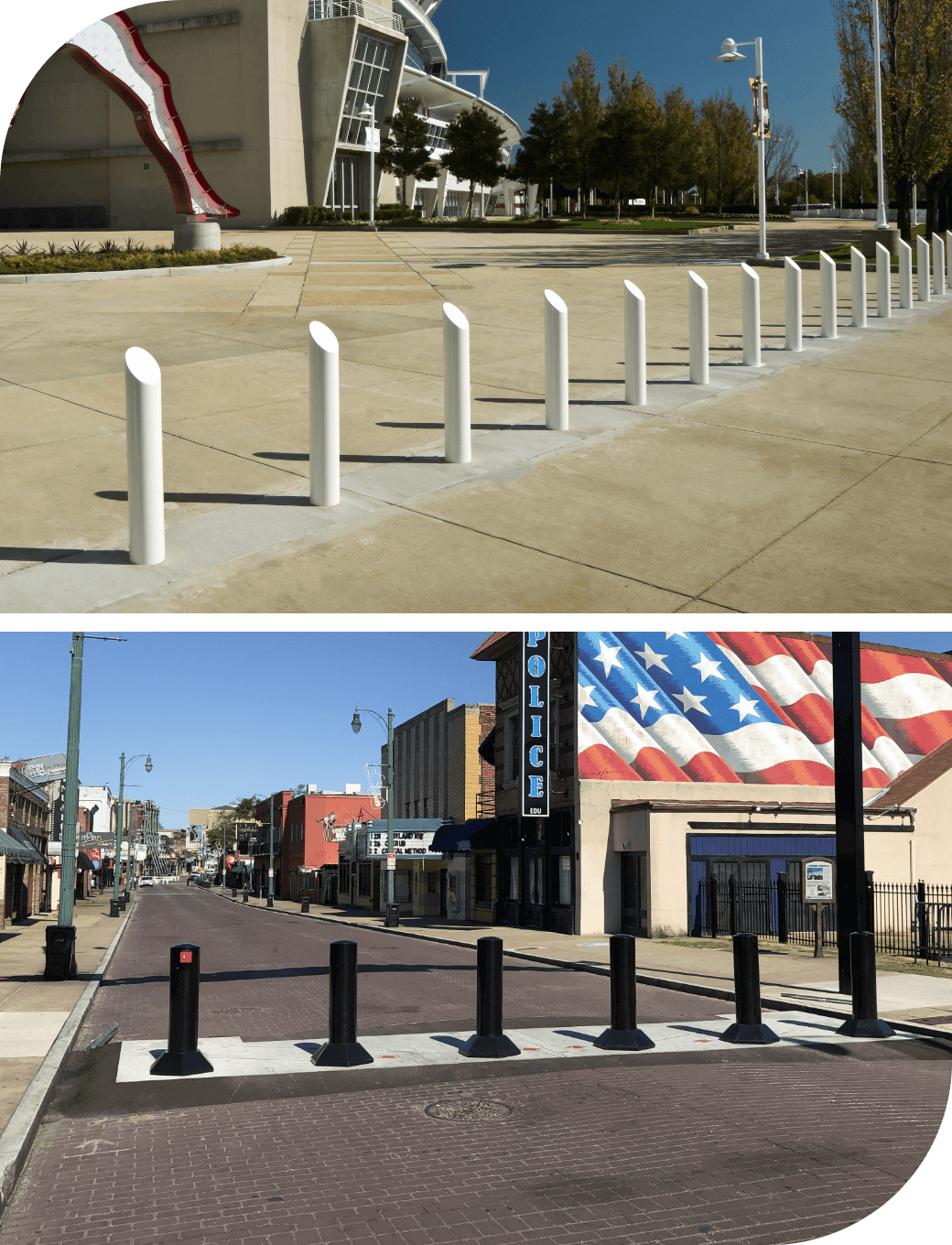

Perimeter Security

Challenge. We

have the Solution.

We have the people, solutions, and —most importantly—

proven track record of excellence to turn your challenge

into done (right).

Search for solutions, products and

documents on our website. Not sure which

solutions suit you? We can help!

We’re here to serve you

Question?

Product or Solution need?

Fill out the form and we’ll be in touch

(typically in less than four hours, Monday-Friday,

7am – 6pm Eastern Standard time)

Need Immediate Help?

Let’s get you to a Solution

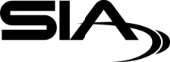

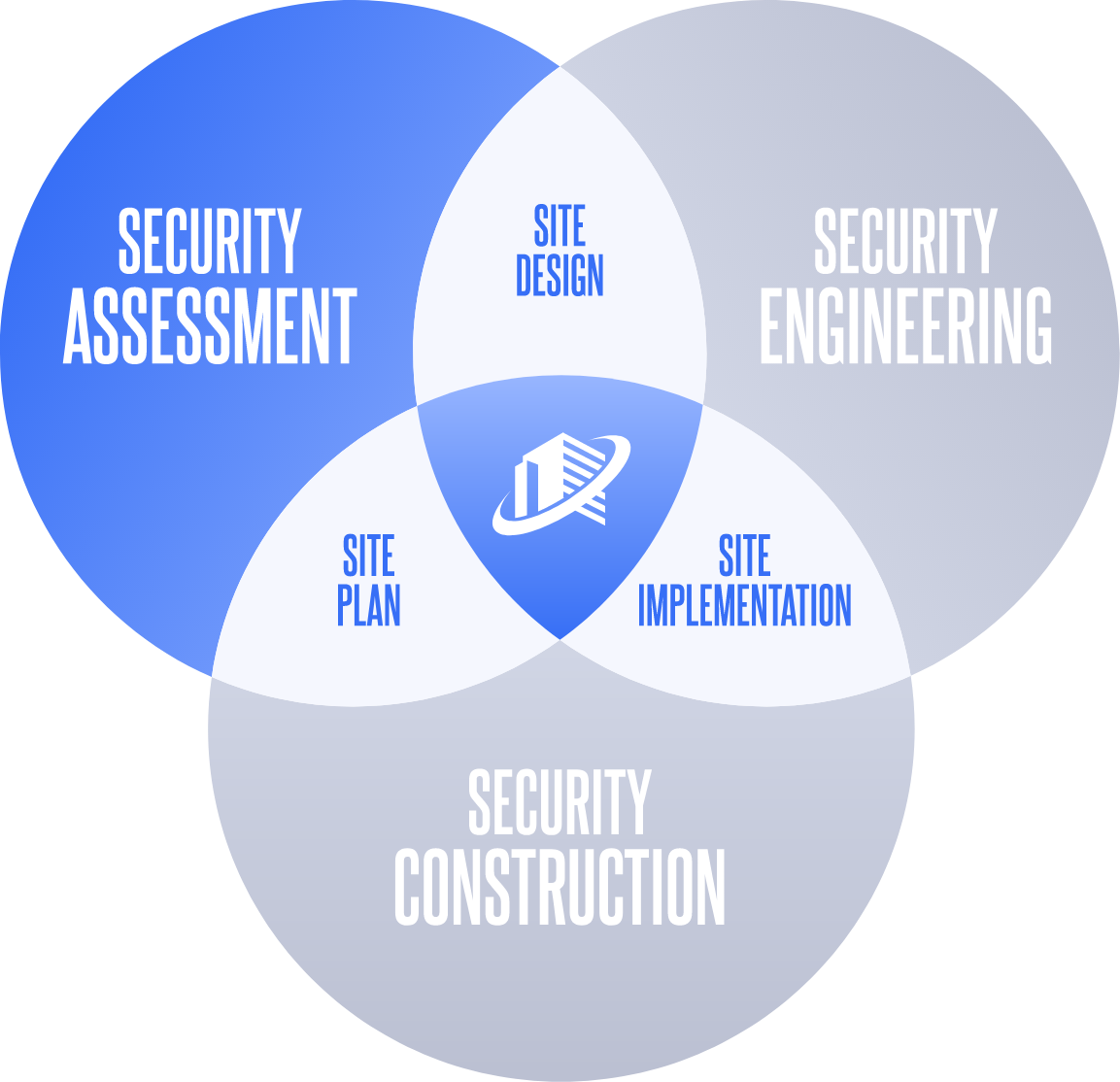

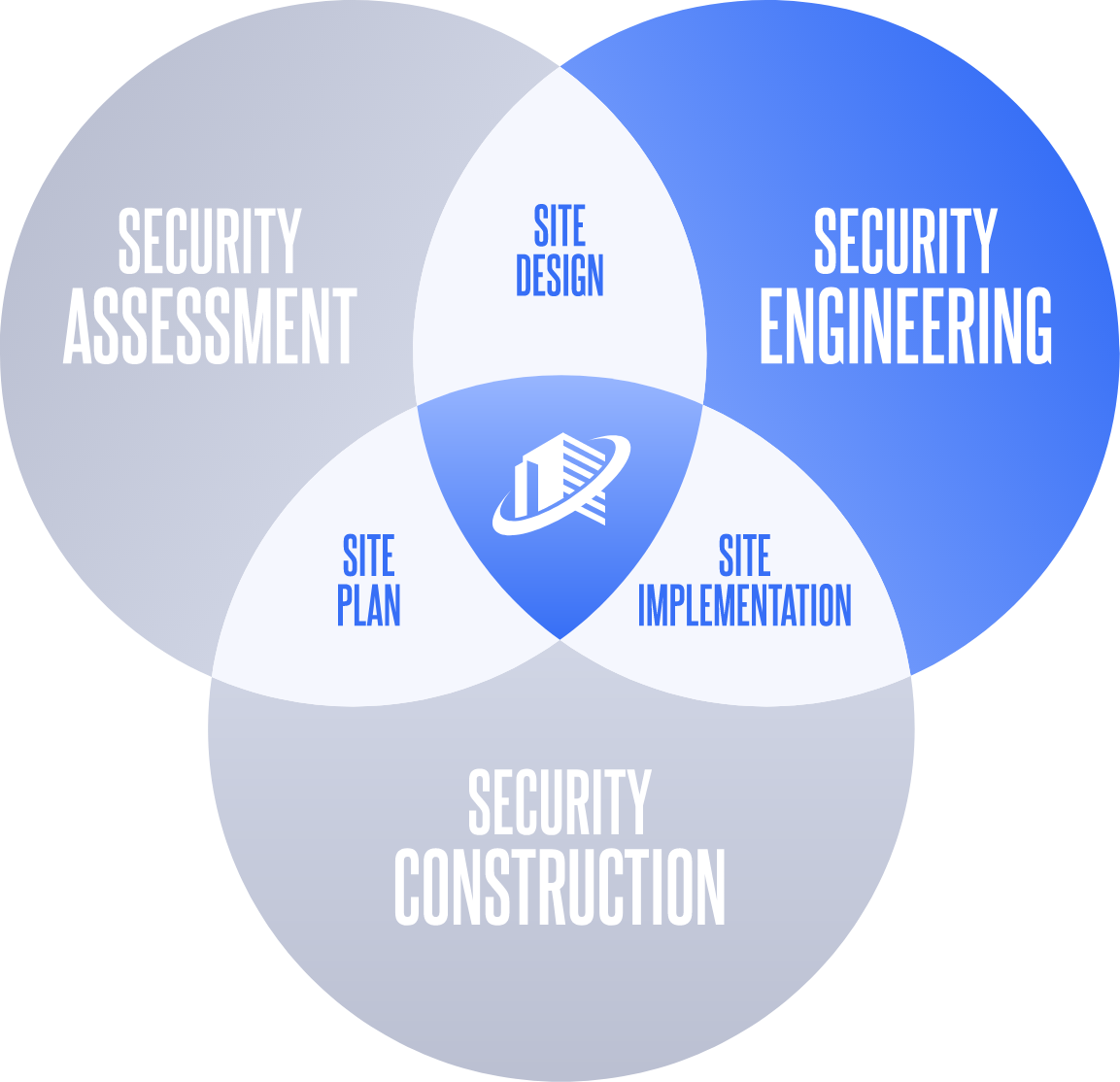

Assessments

Our team is available to assist in assessing the requirements of a new project or the current conditions of an existing site.

We specialize in

- Site Characteristics

- Vulnerability Assessment

- Vector Analysis

- Blast Analysis

- Threat Verification

- Stakeholder Input

Engineering

Concentric Security Consulting provides a wide range of services to support an existing facility, potential leased facility or new facility design.

We specialize in:

- Technology Selection

- Civil Review

- Existing Infrastructure

- Underground Encumbrances

- Drainage

- Layout Design

Construction

Concentric Security provides a wide range of services to support an existing facility, potential leased facility and access control point construction.

We specialize in

- Submittals

- Materials Procurement

- Installation

- Verification Testing

- Training

- Warranty & Service

Service

Service Division is devoted to delivering on our commitment to our customers of providing outstanding customer service…

We specialize in

- Barriers of All Types

- Preventative

- Controls

- Minor Repairs

Trusted by over 5,000 business owners

in the US since 2005

“Working with Concentric Security has been an awesome and a great experience. The integrity they bring to their operations and the quality control of their work, is superior. They’ve taken care of us, while always being honest and straightforward with us. The options they gave allow us to be successful and provide for a safer environment.”

Security Director

Professional Sports Team

“Thank you for your support in getting the barrier back in service! It significantly improves the traffic safety at our site. The Concentric Security technician was outstanding! He stayed connected and kept me apprised of his projected arrival time. Once he got here, he was able to diagnose and repair the problem. Thanks to all who supported us in these efforts!”

Chief Building Officer

Secure Government Facility

“Cold weather can be the ultimate challenge to maintaining and repairing barrier equipment. It is also a challenge to keep a good attitude, keep warm, and keep safe. I called for service, thinking that most technicians would show up in 19 degree weather, with the equipment packed with snow, and say there was nothing that could be done until the snow was gone. Your technician did none of that. He removed the snow, had a great attitude, and stayed until he was able to diagnose the issue and fix the problem. I appreciate your technician’s professionalism and representing what a true expert technician looks and acts like. Thank you Concentric!”

Assistant Chief Engineer

Secure Federal Facility

Thank you Concentric! The team that came out to complete the gate repair was a class act. These guys were polite, courteous, professional, and fast. Nice work Concentric team, we appreciate the great partnership!

Long Time Commercial Customer

“Bollards outside of non-landmark or

non-government buildings are

usually intended to protect

pedestrians, not buildings.”

David Wachs

Concentric Security President in Newsweek on

NYC Presidential Election Security Measures

“Any place there are large gatherings

of people, it is being addressed and

at least considered more and more in

this country,” he says… “There is a

much higher awareness of vehicular

attacks.”

David Wachs

Concentric Security President in Newsweek on

NYC Presidential Election Security Measures

Valued Suppliers